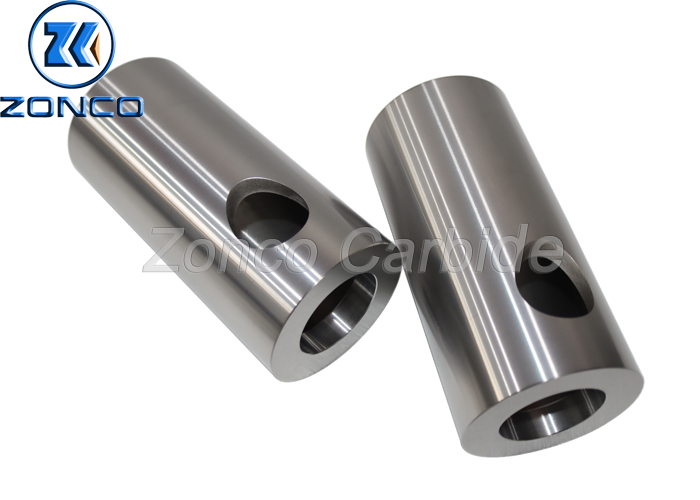

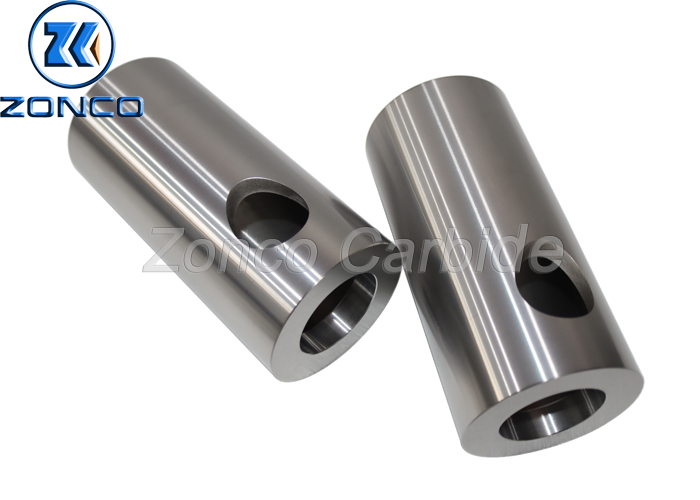

Tungsten Carbide Bushing For Water Pump

Quick Details

| Application: Oil Industry | Model Type:Customized | Trade Term: CIF,EXW,FOB |

| Material: Tungsten Carbide | Product Name: Carbide Bushing | Surface Roughness: 1.6~0.1 |

| Trial Order: Acceptable | OEM Service: Acceptable | Delivery Time: Shipped in 10 days after payment |

Product Description

Carbide bushings are mainly used for stamping and stretching.

Carbide bush can effectively reduce the friction between the punch

or the bearing and the equipment, and achieve a guiding effect to

help protect the equipment. As a wear part in petroleum machinery

wells, cemented carbide bushings have high hardness, good wear

resistance and high smoothness. After welding, the hardness of the

carbide bushing can reach HRC60, and the wear resistance is better,

which can meet the requirements of the petroleum machinery

industry.

As a professional Chinese manufacturer and supplier, we specializes

in design, development, precision of wear resistant components and

new materials research and production, marketing, meanwhile, we

offer cost effective products and material option solution for

those customers who seek high performance products used in extreme

complex working condition.Main products: hard alloy wear-resistant

parts, metal matrix composite wear-resistant parts, superhard

powder materials, etc. Work with us, you will benefit financially

and

conveniently from our good quality and services, and competitive

prices.

Product show

| Common Alloy Grades, Ghysical Mechanical Properties And Recommended

Application |

| Grade | WC% | Co/Ni % | Physical and mechanical properties | Grain size (μm) | Recommended application |

| Density (g/cm3) | TRS (N/mm2) | Hardness (HRA) |

| ZG01 | 100 | 0 | 15.3-15.5 | 1200 | 95.5 | 0.3 | Ultra-high hardness, high wear resistance, anti-corrosion, with

certain anti-destructive ability |

| ZG04X | 96 | 4 | 15.0-15.2 | 1600 | 92.8 | 0.8-1.0 | Suitable for drawing die, non-ferrous metal wire drawing and

wear-resistant parts |

| ZG06 | 94 | 6 | 14.8-15.1 | 2500 | 90.0 | 1.2 | Good abrasion resistance, good compression resistance, suitable for

wear-resistant parts that resist abrasion and high pressure. |

| ZG06X | 94 | 6 | 14.8-15.1 | 2400 | 91.5 | 1.0 | Superio wear resistance,good comprehensive properties,suitable for

making non-standard structure components with higher wear

resistance. |

| ZG06A | 94 | 6 | 14.8-15.1 | 2150 | 92.5 | 0.6-0.8 |

| ZG08 | 92 | 8 | 14.6-14.9 | 2700 | 89.0 | 1.2-1.6 | Good general performance, used for general wear parts, molds,

general tools, etc. |

| ZG10.2 | 90 | 10 | 14.3-14.6 | 3800 | 91.7 | 0.7 | Good general performance, suitable for casing and oil nozzle

products |

| ZG11 | 89 | 11 | 14.3-14.7 | 2800 | 88.5 | 1.2-1.6 | Anti-wear, anti-erosion, good comprehensive mechanical strength,

suitable for wear-resistant parts in the petroleum, chemical and

mechanical industries. |

| ZG12X | 88 | 12 | 14.2-14.5 | 3000 | 89.5 | 1.0-1.2 | Anti-erosion, good comprehensive mechanical strength, suitable for

impact-resistant wear-resistant parts, molds, and roller rings. |

| ZG15 | 85 | 15 | 13.8-14.2 | 3000 | 86.5 | 1.2-1.6 |

| ZG15X | 85 | 15 | 13.8-14.2 | 4500 | 89.0 | 0.7 | Excellent wear resistance and toughness,it is suitable for making

integral stamping dies, anti-vibration toolholders, etc. |

| ZG20 | 80 | 20 | 13.4-13.8 | 3100 | 85.0 | 1.0 | Excellent wear resistance and toughness |

| ZN06 | 94 | 6 | 14.5-14.9 | 2000 | 90.0 | 1.2 | Non-magnetic alloy, suitable for sealing ring, non-magnetic

wear-resistant parts and corrosion-resistant parts. |

| ZN09 | 91 | 9 | 14.3-14.6 | 2300 | 89.0 | 1.2-1.6 |

| ZN11 | 89 | 11 | 14.0-14.3 | 2600 | 88.0 | 1.2 |