Zhuzhou Zonco Sinotech Wear-resistant Material Co., Ltd.

Zhuzhou Zonco Sinotech Wear-resistant Material Co,. LTD. is a

factory which is focused on precision of wear resistant components

and new materials research and production, marketing, meanwhile, we

offer cost effective products and material option solution for

those customers who seek high performance products used in extreme

complex working condition.

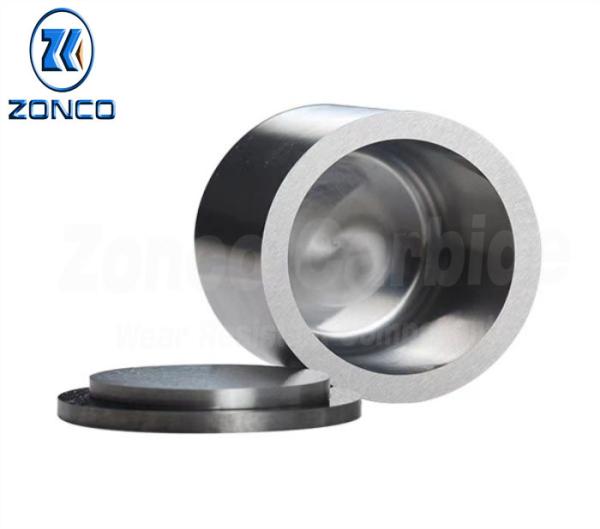

Main products: hard alloy wear-resistant parts, metal matrix

composite wear-resistant parts, superhard powder materials, etc.Our

company has a strong ability of transforming scientific research to

actual production. We can make large quantity with low cost. The

products are widely used in oil and natural gas drilling and

mining,chemical industry, coal chemical industry, pump valve, solar

energy, nuclear energy, military industry, automobile, mining

construction machinery, advanced materials and other industries.